Crafting Success

At SolidLine, our skilled team operates an aluminum mold factory, specializing in the creation of custom molds for aluminum framing and windows. Each mold is meticulously crafted to meet specific profile requirements, playing a critical role in shaping the aluminum bars post-extrusion. This process is an integral part of our production line, seamlessly connecting various stages in the manufacturing process of our high-quality aluminum products.

The creation of an aluminum mold demands a collaborative effort from different departments. The product quality is greatly influenced by the precision and quality of the aluminum mold, making cross-departmental cooperation a fundamental aspect of the process.

Get started

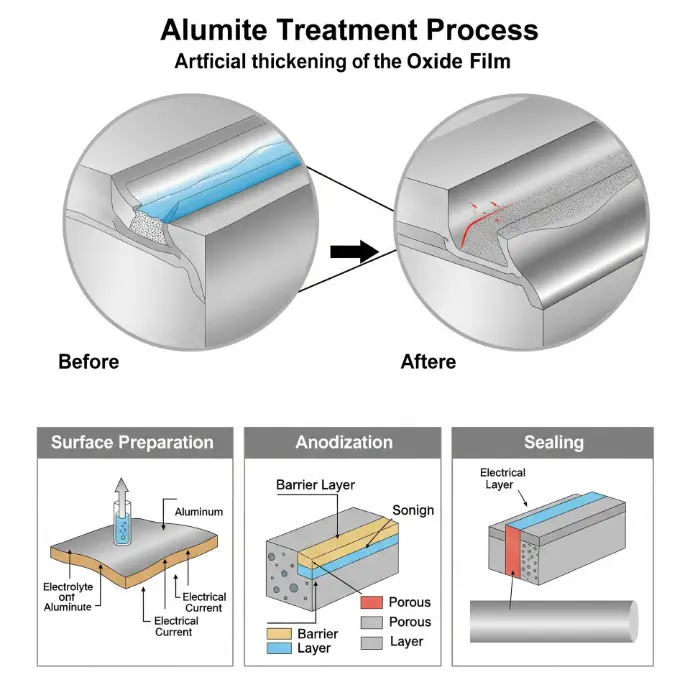

SURFACE TREATMENT TECHNOLOGY

At SolidLine, we understand the importance of surface treatment for extruded aluminum products used in our framing and windows. This critical step prevents color changes and surface corrosion, ensuring longevity and maintaining the aesthetic appeal of our products.

CASTING TECHNOLOGY

The aluminum alloys utilized in our factory adhere to current state standards, ensuring the quality and reliability of our products. We use specific alloys, such as 6005 and 6061, for civil applications, and 6063 for construction purposes. Each aluminum alloy has varying percentages of mixed metals.

EXTRUSION TECHNOLOGY

The precise heating of molds and billets is essential, as any imprecision can affect the shape of the aluminum following the extrusion process. Post-extrusion, the billet is cooled using a steam and air system to ensure proper setting.